We, “Avani Pack Wrap Private Limited”, established in the year of 2020 are leading Manufacturer Surafce Protection Film BOPP Tapes and many products imports like Foam Tapes, Masking Tapes, Tissue Tapes, Reflective Tapes etc.

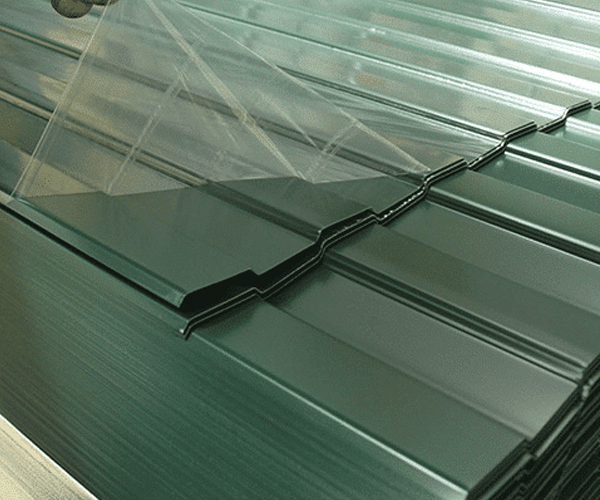

Pre-Coated Metals

Pre-Coated Metals refer to metal sheets or coils that have been coated with a protective or decorative layer before being shaped into end products. This coating is typically applied in a controlled factory setting using processes like coil coating, which ensures uniform thickness, better adhesion, and durability. Common base metals include steel and aluminum, while coatings may consist of paints, polymers, or laminates. Pre-coated metals are widely used in industries such as construction, automotive, and appliances due to their enhanced corrosion resistance, aesthetic appeal, and reduced need for post-fabrication finishing. This not only improves product quality but also increases manufacturing efficiency and reduces environmental impact.

Key Features

Smooth Wrinkle Free Unwinding

Tear and Puncture Resistance

100 % Recyclable and Environment Friendly

High Durability

Residue Free Peel-Off

Application

1

Sandwich PUF Panel

2

Roofing Sheet Protection Film

3

Fire Metal Doors

4

Appliance Metal

5

Modular Partitions

6

Clean Room Equipment

Technical Specification

| Thickness (mic) | 30 to 80 Micron |

|---|---|

| Film Color | Clear |

| Adhesive Type | Water Acrylic |

| Width | Up to 1550 mm |

| Printing | Up to 4 Color |

| Tensile Strength | As per product surface requirement |

| Elongation | As per product surface requirement |

| Adhesive Strength (gms/25mm) | 50-300 |